Free Download ANSYS EMC Plus & Charge Plus 2024 R1 | 10.3 Gb

Owner:ANSYS & Electro Magnetic Applications, Inc. (EMA)

Product Name:EMC Plus & Charge Plus

Version:2024 R1

Supported Architectures:x64

Website Home Page :www.ansys.com

Languages Supported:english

System Requirements:Windows *

Size:10.3 Gb

Electro Magnetic Applications, Inc. (EMA) and Ansysis pleased to announce the availability of EMC Plus & Charge Plus 2024 R1 is industry-leading simulation solution portfolio, addressing critical design and safety needs for applications ranging from space exploration to everyday commutes.

Ansys EMC Plus What’s New 2024 R1

This new release makes running simulations faster and makes it easier for full-vehicle EMI/EMC analysis. 2024 R1 featured updates include: GPU accelerated solver 3D field and current visualization Transfer impedance simulator Cable wiring connectivity automatic assignment to 3D cables from mechanical CAD "We’re very.

– GPU accelerated solver

– 3D field and current visualization

– Transfer impedance simulator

– Cable wiring connectivity automatic assignment to 3D cables from mechanical CAD

GPU Accelerated Solver

New in 2024 R1, EMC Plus now supports GPU (graphics processing unit) acceleration. The solver runs on Linux platforms. Simulations can be run utilizing multiple GPUs in parallel. This leads to significantly shorter run times than pure CPU (central processing unit) simulation. Benchmarks show inexpensive GPUs simulate four times faster than using a multi-core CPU alone. Scaling on multiple GPUs and more performant GPU hardware shows additional speed improvement. EMC Plus will work as it always has, but now new binaries will call a special version of the software that will utilize GPU calls. If the machine has a GPU, the user just needs to specify the number of cards that will be used.

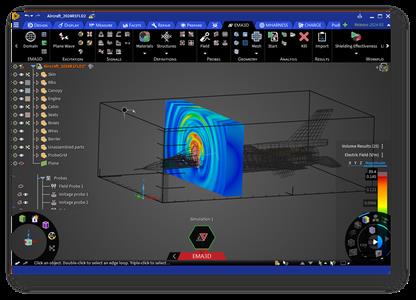

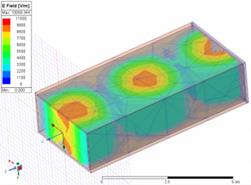

3D Field and Current Visualization

Our second highlighted feature is the ability to visualize quantities in 3D. This update will help to better communicate product performance from an electromagnetic standpoint. This feature quickly visualizes quantities, such as electric fields, magnetic fields, and electric current, in 3D. To start, users need to create a box to contain the fields to probe. Once a quantity has been specified, users have the option to specify the time range the results will show, this is seen in Figure 1. After running the simulation, the results are superimposed on the geometry, Figure 2. Clipping planes slice through the results to find the regions for users to inspect.

Fig. 1. Ansys EMC Plus setting to show options for 3D visualization

Users have the ability to select which timestep to view and the field/ current quantity and X, Y, Z, or the magnitude may be specified. When viewing the results, the maximum and minimum range in the legend is interactive. The slice tools allows users to change which part of the 3D space is visible.

Fig. 2. 3D results shown on the model.

As an example, if you have an enclosure, there are fields that may be coming in through different apertures or coupling mechanisms. This new visualization will show hot spots to determine where you have coupling. In a radiation problem you will be able to visualize the radiation pattern in the far field from the antenna. This tool uses the native Ansys Discovery visualization engine to set up the simulation, run the simulation, and visualize the results.

Transfer Impedance Simulator

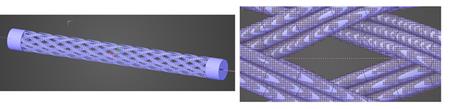

The third highlighted new feature for 2024 R1 is the addition of a transfer impedance simulator. This will allow users to predict the transfer impedance of a braided shield. McDonald says the new feature gives users a way to do that with the least amount of effort possible since every aspect of the simulation is automated. Braided cables have imperfections, or small holes, that allow fields to couple through, this can be seen in Figure 3. These holes can allow fields to couple inside the braids. Transfer impedance is an important method of assessing the shielding effectiveness of the cable while doing it in an intrinsic way that does not change from measurement to measurement.

Fig. 3. Left: Overbraid CAD. Right: Close-up of mesh superimposed on the braid geometry.

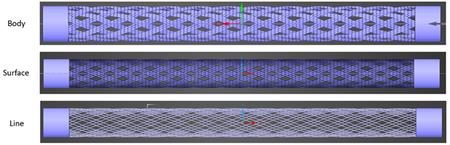

EMA has existing analytical models for transfer impedance, and it is an important metric used in the MHARNESS solver of EMC Plus as a frequency-dependent measure of the shielding of a cable braid. This new feature uses full-wave simulation which will lead to more accurate results. This is an automated workflow. The braid geometry is automatically created based on input specifications, such as stands, carriers, and weave angle. Once a CAD model has been generated, the software creates the appropriate domain, source, and probe definitions. EMC Plus also meshes the geometry and executes the simulation. Users also have the ability to change settings for fine control over the geometry and model type. Each individual carrier in the braid can be defined as either a line, surface, or a body, seen in Figure 5. McDonald says the surface or line representations simulate much faster, but they are not as accurate as the body representation. He says the body simulation is the highest fidelity but has the highest computational cost.

Fig. 5. EMC Plus allows for flexible braid modeling.

Other customizable pieces of the model include multiple types of weave angles in the cables and carriers that create different gaps seen in braided cables. Also, the radius of the overall shield, the number of carriers, the number of individual strands, wire diameters, pitch angle, the overall length of the cable, and the excitation frequency that the user wants to focus on.

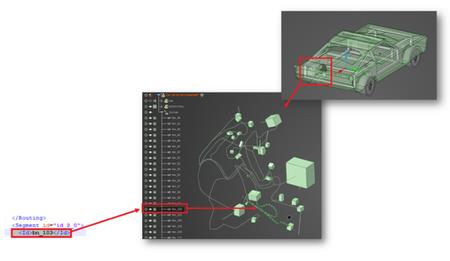

Cable Wiring Connectivity Automatic Assignment to 3D Cable from Mechanical CAD

Featured highlight number four is the ability to automatically assign cable wire connectivity data to 3D cables from mechanical CAD. This makes full vehicle simulation easier. In automotive applications, cables are represented in cable database software, often called wiring diagrams, and are typically a wire board representation. This will tell the user information such as which electronic device is connected to another electronic device and the number of pins that are connected. These are represented as KBL files. This is inherently a two-dimensional process. If the user needs the 3D path of the cables, it is contained within 3D mechanical computer aided design (mCAD). The latest update to EMC Plus can automatically merge the cable wiring connectivity information and the 3D path of the cables based on the segment identifying names. If 3D geometry of the harness route exists, it can be used to map the 2D wiring to the correct 3D location. The lines representing harness routes should be labeled with the correct segment identifier matching the labels in the cable database software file, Figure 6.

Fig. 6. Cable database wiring diagram mapping to 3D geometry.

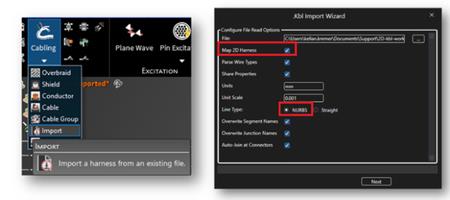

To merge the two separate pieces of information, users have to start by importing the 2D wiring diagram file from the cable database software. To map the 2D wiring diagram file to the 3D geometry, the "Map 2D Harness" box must be checked, Figure 7. Use NURBS as the line type. By pressing the next button, the mapping process is initiated and a 3D KBL file is created.

Fig. 7. Setting in EMC Plus to import 2D wiring.

After clicking next, users can select which segments to import, Fig. 8. The geometry for each segment can also be selected from the wiring diagram file or assigned to a curve in the model manually. By right clicking you can select all.

Fig. 8. Setting the geometry source from file.

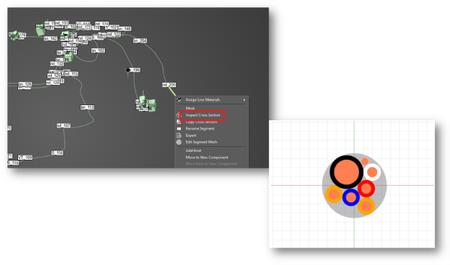

Once the import wizard finishes the harness import the 3D harness will be visible and the cross section of each segment can be visualized. By right clicking on a segment, you can choose to see the cross section, Fig. 9.

Fig. 9. Viewing the imported harness.

Other Updates

These are just four of several updates released in 2024 R1. The others include:

– Non-circular multiconductor transmission line conductor cross sections

– Direct mesh editing features

– Radiation pattern probe

– Auto-alignment of 3D mesh edges to geometry

– PCB geometry import improvements

– Standalone transient circuit solver

– STK and EMC Plus lightning probability tool

– Specific absorption rate modeling

Ansys Charge Plus 2024 R1 What’s New

This latest release focuses on adding new capabilities to improve the user experience and workflow efficiency. 2024 R1 featured updates include: New integrated data processing tools GPU accelerated FDTD solver Mesh updates HFSS field import for FEM New PIC emission models Radiation hardening one-click workflow Charge Plus.

– New integrated data processing tools

– GPU accelerated FDTD solver

– Mesh updates

– HFSS field import for FEM

– New PIC emission models

– Radiation hardening one-click workflow

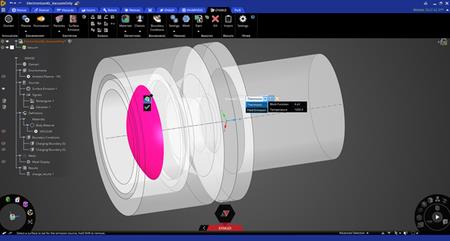

New Integrated Data Processing Tools

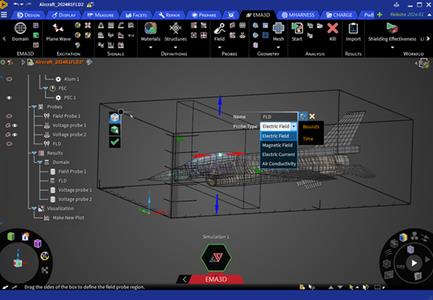

In 2024 R1, Charge Plus is integrating further with the Ansys Discovery interface. Discovery now plugs into Ansys Graphite to better visualize data in 3D, including overlaying results on top of the 3D CAD model. Users can visualize quantities in 3D quickly by creating a box to contain the fields to probe, Figure 1. Next the probe type is classified as either electric field, magnetic field, electric current, or air conductivity. Optionally, users can specify the time range which the results will be visualized along with the period between capturing results. After running the simulation, the results are superimposed on the geometry. Clipping planes slice through the results to find the region for users to inspect.

Figure 1. New visualization starts by creating a box to contain the fields to probe.

This new feature will allow users to easily locate where arcs and sparks are happening in a given system. Additional features available in the visualization tool include better monitoring of variables related to radiation hardening, the fluid solver, and the particle-in-cell (PIC) solver. Extra probes have been added, specifically for the finite element method (FEM) solver. Previously, users had to look at the data, such as the potential average, over the whole system. Now users can select a given body in the model and report on the data specifically.

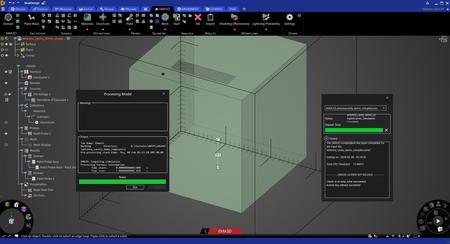

GPU Accelerated FDTD Solver

Charge Plus now supports GPU acceleration for faster simulation times compared to CPU simulation. The solver runs on Linux platforms and simulations may be run utilizing multiple GPUs in parallel. Benchmarks show inexpensive GPUs simulate four times faster. Scaling on multiple GPUs and more performant GPU hardware shows additional speed improvement. For example, a full system ESD on PCB model with variable mesh and nonlinear air chemistry was run on a 3GB Ram desktop once using CPU and once using GPU. The simulation had 52 million mesh elements and 460,000 time steps. The compute time on the CPU was 1,866 minutes. On the GPU it was 471 minutes. Showing that the GPU run time was four times faster than the CPU.

Mesh Updates

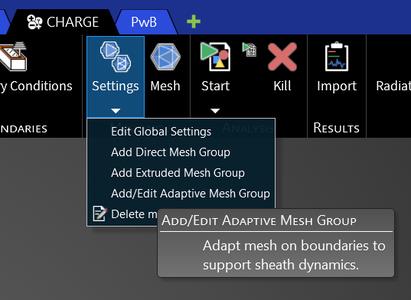

In this release, adaptive mesh group layers have been added to support plasma enhanced chemical vapor deposition (PECVD) workflow, specifically the PIC and fluid solvers. Users are now able to define a very thin mesh near the boundaries of the problem space. These plasma regions are typically called plasma sheaths and are critical for the calculation of electromagnetic fields and the distribution of particles within the chamber. Plasma sheaths can easily be looked at within Charge Plus using the adaptive mesh group feature. It is found by clicking on Settings then Add/Edit Adaptive Mesh Group as shown in Figure 3.

Fig. 3. Adaptive Mesh Group can be found under the settings tab.

HFSS Field Import for FEM

2024 R1 features a new way to import electromagnetic fields from Ansys HFSS to the FEM solver. Waveguides are created in HFSS and the modes are imported into Charge Plus. The mode that was imported from the waveguide is shown on the left in Figure 5. The results are shown on the right of Figure 5 and depict the magnitude of the electromagnetic field.

Fig. 5. Imported waveguide from HFSS (left). Results shown in Charge Plus (right).

Inside of the plastic bottle that is being simulated in Figure 5, a thin coating of glass could be added. To simulate that material, the user would want to use the PEVD method. By importing the fields from the HFSS simulation users can see the electron and ion distributions inside the bottle that results from those fields. Users can then calculate the deposition efficiency and the deposition process within the bottle.

New PIC Emission Models

Four new PIC surface emission models and space charge limiting models have been added in 2024 R1. This includes:

– Thermionic Emission and Schottky Emission

– Space Charge Limited Emission

– Secondary Electron Yield Emission

– Field Emission (Cold Field Emission > 1E8 V/m)

In PIC solver models, typically electrons and ions are responding to electromagnetic fields in an ambient electron environment at a given volume. As of 24R1, users now have the capability to use various types of emission models for these electrons to better model realistic environments, including harsh environments where fields are very intense. To model these electron generation events, a boundary condition will be defined with the various currents. This will define the number of electrons to be generated from that surface. The thermionic emission and Schottky emission give users the ability to define the number of electrons that would be generated from a heated electrode based on the electromagnetic fields that would be present in a certain system. This applies to electron gun simulations, as seen in Figure 6.

Fig. 6. Election gun modeling in PIC solver

Modeling space limited emission is now also possible. This method is explicitly modeled by our physics solver. Plasma sheaths are modeled, and field distributions are used to update the fields near cathodes using the adaptive mesh that was also released in 2024 R1. Secondary emission models are better simulated with the use of EMA’s Space Environment and Radiation Effects (SERE) test chamber. In this model, secondary election yield parameters are defined. EMA does this using the SERE chamber. Once testing is complete the data is imported into Charge Plus. This allows users to solve problems such as multiple action or various charging effects that would be seen in space. The final new method is the field emission model. This is an emission of electrons when the fields are very high, more than 1E8 V/m. or when gaps are very small. For example, electrons in a piece of metal will tunnel through the surface of that metal and be emitted through a vacuum gap. To be able to model the discharges in the small gaps, users will need to use the field emission model. This is made possible thanks to the FEM solver.

Radiation Hardening One-Click Workflow

A new automatic workflow for radiation hardening has been added to Charge Plus. Users are able to connect to Ansys STK and get energy spectra for a specific ephemeris. To start the automatic workflow, users need to head to the Charge ribbon and click the arrow beneath the radiation hardening button and select settings. Within the settings menu, change the number of time steps to one and update the STK satellite name to ‘MySat.’ Click ‘Run on Complete’ to start the simulation.

Ansys Charge Plus

Along with these capabilities, Charge Plus integrates with multiple other Ansys products, including:

– Discovery

– System Coupling

– Materials

– HFSS

– EMC Plus

– Fluent

– Rocky

– STK

– Chemkin-Pro

The use ofAnsys Electronicssolution suite minimizes the testing costs, ensures regulatory compliance, improves reliability and drastically reduces your product development time.

Ansys EMC Plus (formerly EMA3D Cable)is a 3D Finite-Difference Time-Domain (FDTD) solver with an integrated multi-conductor transmission line solver. The two electromagnetic solvers co-simulate to allow for a complex cable harness to be accurately modeled inside complex geometry, such as an electronic device, a piece of machinery, an automobile or an aircraft. Ansys EMC Plus has been validated on several high-profile aerospace platforms and the results were published at major conferences.

Ansys Charge Plus (formerly EMA3D Charge)is the simulation software designed for the analysis of charging and discharging phenomena. It uses time-domain solvers to simulate electric arcing, material surface and internal charging, 3D particle transport, and dielectric breakdown. It can be used to assess and manage risks associated with excessive charge build up in a product where electrification is a concern. Ansys Charge Plus is used at the design phase for the prevention of material degradation, surface flashovers, and EM interference in harsh radiation environments or high voltage systems. Charging effects due to high-energy particles, precipitation static, low-energy plasmas, solar illumination, and friction electrification may be extremely consequential. With Ansys Charge Plus it is possible to study electric charge imbalance in both space and ground applications. The numerical solutions designed to tackle surface charging, internal charging, and air or dielectric breakdown are combined into streamlined workflow incorporated into the Ansys Discovery | 3D Product Simulation Software. In this optimized workflow, one can easily prepare 3D CAD models, assign charging material properties and environments, mesh your model, run, and analyze simulations.

Ansys EMA3D Cable for Cable Harness Simulation

ANSYSis the global leader in engineering simulation. We help the world’s most innovative companies deliver radically better products to their customers. By offering the best and broadest portfolio of engineering simulation software, we help them solve the most complex design challenges and engineer products limited only by imagination.

Electro Magnetic Applications, Inc. (EMA) is a global leader in providing simulation, consulting and measurement services in the technical areas of electromagnetic effects. Specific specialties include lightning direct and indirect effects, high intensity radiated fields (HIRF), precipitation static (P-Static), electromagnetic pulse (EMP), EMI/EMC, spacecraft charging, RF interference, installed antenna performance and radar signature prediction. EMA and Ansys are collaborating to deliver an enhanced design-to-validation workflow for certifying cable harness models in aircraft and automobiles. The workflow greatly reduces electromagnetic interference (EMI) risks to cable harnesses, slashes development time, speeds certification and expedites new products to market faster than ever.

peeplink.in/75d742027dc2

NitroFlare

1f76f.setup.part1.rar

1f76f.setup.part2.rar

1f76f.setup.part3.rar

Uploadgig

1f76f.setup.part1.rar

1f76f.setup.part2.rar

1f76f.setup.part3.rar

Leave a Reply

You must be logged in to post a comment.