Free Download Altair Inspire Extrude 2024.0 | 4.6 Gb

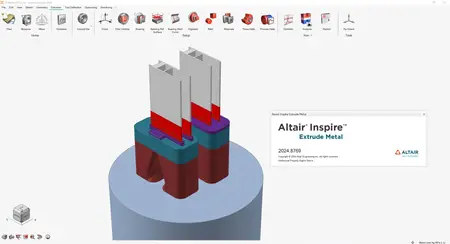

Altairhas releasedInspire Extrude 2024.0is an easy-to-use tool for simulating metal extrusion, polymer extrusion, and friction stir welding processes to detect potential defects early in the product development phase and improve the process efficiency.

Owner:Altair

Product Name:Inspire Extrude

Version:2024.0

Supported Architectures:x64

Website Home Page :www.altair.com

Languages Supported:english

System Requirements:Windows *

Size:4.6 Gb

New Features and Enhancements 2024

The Inspire Extrude 2024 release includes the following new features and enhancements.

General

Additional Parameters

Users can set the additional parameters in a ✅File Named "AdditionalParameters.txt", and it will automatically be copied to the run folder. This feature will utilize new features in solvers that are not yet supported in the interface.

Metal Extrusion

Profile Die Creation

A new feature to create a profile die with a pocket is implemented. It will support multi-hole die. The presence of a pocket is optional. This is part of the die creation initiative. With this new implementation, we have three features for die creation. (INSTRUDE-3512)

Tool Deflection

Quick Analysis using SimSolid

Real-time elastic analysis with assumed loads using SimSolid is implemented in this release. This will help the users evaluate the performance of the tool stack and help improve the design before embarking on a detailed stress analysis based on computed loads with OptiStruct. (INSTRUDE-3444)

Polymer Extrusion

Roller BC

The interface now supports the specification of the roller boundary condition. Users can specify the RPM and the temperature of the roller. The interface will automatically determine the roller center and the diameter. Automatic meshing does not support models with rollers and the user will have to use the "start with existing mesh" option. This feature will help set up tire extrusion models that use rollers.

Improvement in Automatic Part Renaming Inconsistency in the automatic renaming of the created/organized components is removed. Now they will be named a Plate_L. For example, parts from die plate 3, will be named Plate3_L1, Plate3_L2, etc. (INSTRUDE-3514)

The following issues have been resolved for the 2024 release:

General:

– Avoid writing two H3D files: Inspire Extrude needs an SI unit H3D file to post-process the results. The solver has options to write results in SI units, user units, or both. The previous default was to write both files. Now it is updated to write only in user units. Inspire Extrude can automatically translate this to SI units and enable post-processing. This functionality had issues since the past few releases. This issue is resolved in this release. (INSTRUDE-3525)

– Mixed element types in components – H3D Writer: In the previous release, speed up of H3D file export was implemented, and this process assumed that a component/part will have only one type of element. This introduced failures when this assumption was violated. This issue is resolved now. (HXT-730, HXT-731, HXT-734)

Metal Extrusion:

– Descriptionting Inconsistencies in the Extrusion Limit Diagram: The ELD (Extrusion Limit Diagram) was Descriptionted only correctly in metric units. There was an issue with the scale of the y-axis. This issue is resolved now, and the limits of the y-axis are now determined correctly for all unit systems.

– Error running particle trace simulation using the PHX file: There was an error in the writing and reading restart files from large models. This issue is now resolved (HXT-705)

– Random crash while running billet skin simulation: The boundary surface data that is written to the FEM file assumed that each boundary component had only one type of element, but in the case of billet skin, the surface consisted of a mix of triangular and quadrilateral faces. This issue is resolved now. (HXT-730)

Polymer Extrusion:

– Polymer with Insert – BC creation improvement: Models with inserts had issues in automatically extracting boundary conditions in solid-fluid interface regions. This issue is resolved in this release. (INSTRUDE-3481)

– Prism elements in Insert were not written correctly in the H3D file: This issue was caused by mixed element types in insert components and it was resolved with the H3D writer enhancement. (HXT-731, HXT-734 )

– Profiles sometimes show non-physical deformation with puller speed: In some models, the profile shows displacement hotspots in the exit layer of the profile. This issue is resolved. (HXT-732)

Altair Inspire Extrudeis a simulation environment designed to help extrusion companies meet the ever increasing demands to produce complex profiles with tight tolerances, quality surface finishes, and high strength properties at reduced cost. Altair Inspire Extrude is a simulation solution for both metal and polymer extrusion. It helps achieve productivity gains by reducing product development costs and improve extrusion quality, increasing production yield. Altair Inspire Extrude is a virtual press where users can visualize material flow and temperature inside a die during extrusion and make necessary changes to ensure balanced flow, while identifying and eliminating product defects.

Polymer Extrusion in Altair Inspire Extrude

Altairis a global technology company that provides software and cloud solutions in the areas of product development, high performance computing (HPC) and data analytics. Altair enables organizations across broad industry segments to compete more effectively in a connected world while creating a more sustainable future.

Leave a Reply

You must be logged in to post a comment.